Bottling Day:

1. Sanitize 50 bottles. I used

to use One-Step and the sink with fine results (I did buy a sink tub that I only

use for homebrewing stuff. Keeps it neat and clean that way). Now I

have a dishwasher. Other people use the oven. Do whatever works best for you.

Bottles in the dishwasher after they've been sanitized.

Here's my Sani Rinse cycle, so official and all...

2. Sanitize the bottle caps, bottle filler, and racking tube. Could do this at same time you are sanitizing the bottling bucket. Run sanitizer out of bottling bucket spigot again.

3. Sanitizing the racking cane

is a little tricky. What I do is suck the sanitizer up into it and then put my

hand over the end so the sanitizer stays inside of the cane. Then I use my hand

or a sponge and keep bathing the outside of the cane in sanitizer for 2

minutes. I have had no problems doing it this way.

4. Boil 1 pint of water and

add 3/4 to 7/8 cup priming sugar to it. Boil 8 minutes or so, then turn off heat.

I use 1 pint of water and just eyeball the priming sugar to get about 3/4 cup.

5. Put the priming solution in

the bottom of the bucket first! When you rack the beer into it, it will get

thoroughly mixed throughout the beer.

6. Follow the instructions to

siphon the beer from the carboy into the bottling bucket. Most of the time

this works just fine, but sometimes it’s hard to get going. Make sure you have

a tight seal with the orange carboy cap. Might have to grab it tight. I have

never worried about sanitizing my mouth before blowing into the cap, but some

people gargle vodka or something like that.

7. When siphoning I don’t push

the cane all the way down right away. This will stir up more yeast sediment. I

keep it a few inches from the bottom, but try not to let level of the beer get

below the bottom of the cane or siphon will stop, and it can be hard to

restart.

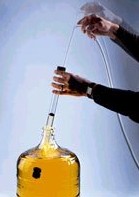

(You will read about the Fermtech

Autosiphon (see pic). I have one but have found that while it always starts and

is easy to start, it doesn’t allow you to get quite as much beer out of the

carboy as a racking cane. Thus I only use it when I have a stuck siphon.

Many people swear by it.)

8. As beer level gets low, tilt carboy so you can get as much as possible without getting too much of the crud. I have taken to propping up the back of the carboy with a 2x4 piece of wood. That tilts the carboy for me.

9. Take a hydrometer sample from

the spigot. Either do readings now, or save it for later. Make sure you taste

it and enjoy the fruit of your labors. Usually I’ll just fill up a small sample

glass, and take the hydrometer readings when bottling is done.

10. Attach bottling tubing and

bottle filler to bottling bucket.

11. I put the sanitized caps in

a bowl and keep them by me.

12. Fill a bottle with beer.

Watch for foam coming up. When foam comes out of mouth, stop. Set bottle

aside.

If you want to get the bottle really full, you can tilt the filler at the top and finish it off.

13. I usually fill about 15

bottles or so before capping them. I sit on the floor when bottling and line

them up against the cupboard. This also gives the bottle a chance to get a

little bit of the oxygen out of the bottle.

14. Capping is not too tough.

You will need to put a little more pressure down than you might think, but you

also don’t want to do too much. If you notice your caps are getting a circular

indentation on top, you are putting a little too much force into it.

I can't cap with one hand, but here is my capper.

15. Now comes the hard part --waiting 2-3 weeks to enjoy your first batch. Some batches will carbonate within a week, but I've found that 2 weeks is a minimum amount of aging that allows the beer to begin to mature. It could take many weeks for the beer to reach its peak flavor, but if you can at least wait 2 weeks, you are doing all right.

Finished product, two cases of potentially great homebrew.

Yeast Starter tips - see the video too

1. Get a glass jug. It could be 1 gallon or 1/2 gallon, depending on the size of your starter. It can be an apple-juice jug or even a cheap wine jug. I use a 1/2 gallon glass growler that ends up being about half full when I am done.

2. You'll need a rubber stopper that fits nicely into this jug. It might be the same size as your carboy's stopper but check it out. You might need an extra airlock too. I just have some extra stoppers and airlocks around. They're cheap.

3. If using a Wyeast Smack Pack, make sure it is fully swollen. Follow directions on yeast pack.

4. I use 1 cup of Light Dry Malt Extract and boil that in 2 or 3 pints water. I try to end up with about 2 pints, or 1/4 gallon. Your desired gravity of the starter is around 1.030-1.040, so that will affect how much DME and water you use. Bring water to a boil (you do not need to use your brew kettle for this). Remove from burner just like you would for a normal beer. Add 1 cup of Light Dry Malt Extract. I usually buy this in a 1-lb bag and that will make 3 yeast starters.

5. Stir in Dry Malt Extract and return to boil. Boil for 15 minutes.

6. Cover and cool in an ice bath like normal.

7. Sanitize your funnel, and pour wort into your sanitized glass jug. Save the sanitizer in a sink or tub.

8. I sanitize my floating thermometer and lower it into the wort (that is now in the glass jug) with a string. If the temp is above 80, I keep the jug in the ice bath for a while until it is cool enough to add the yeast. I suppose you could put a fermometer on your jug but it's probably not worth it. Over time you will learn a method that works for you and you won't need to take the temperature every time.

9. I sanitize the top of the yeast smack pack but setting it upside down in the sanitizer. Then I sanitize a scissors and use that to cut the corner.

Here I'm using a White Lab's pitchable tube, but I usually would be pitching a swollen Wyeast smack pack.

10. Pitch the yeast. I usually use the funnel.

I sanitize one of my hands, cover the mouth, and then shake the starter. Above you can see the foam after the shaking/aerating.

11. Shake the tar out of it (this assumes you have it cool enough) and get lots of bubbles into it. Take off your hand (might want to sanitize your hand that you use) and let more air in. Shake again. I suppose if your jar came with a screw-on lid, you could sanitize that and use it.

12. Attach airlock and stopper. Keep at a temp that is the same as what you plan to ferment your beer at. It might not be necessary, but I keep it out of the light, either by room placement or by putting a t-shirt over it.

This is the next morning. Yeast settles to the bottom. Swirl the starter a couple times a day to get it back into suspension. Also, there is a little krausen in the photo. Sometimes there is more, sometimes less.

13. You will not see tons of vigorous fermenting, but you should see some bubbles form on the top as well as some activity in the airlock. **A couple times a day, gently swirl the yeast off the bottom of the jug to return them to suspension. This helps them consume all of the fermentable sugar and grow to the greatest cell count possible. To keep it continually stirring, you can make a stir plate and see how that works here or here.

Here is the same yeast starter as pictured above 24 hours later. Apparently the yeast decided to kick into high gear and form quite a krausen. You can see the seemingly thin layer of yeast at the bottom. It might not look like much but you can be sure that you will have many more yeast cells than if you just pitch the yeast without making a starter.

14. On brew day, you can either dump off some of the wort (since the yeast are mostly on the bottom) or dump the whole thing in. (If you want to decant the wort off the yeast, put it in the fridge the night before using. This will cold crash the yeast and help them drop to the bottom, making it easier to decant the wort off w/o throwing away anyyeast). Either way, before you pitch make sure no yeast are stuck to the bottom. You want to use as many of the little critters as possible. Also, if using the whole thing, remember its volume is .25 - .5 gallon so don't fill your primary fermenter with 5 gallons of wort before pitching yeast.

15. A new thing I'm trying is cold pitching. You put the yeast starter into the fridge beforehand (hours? a day?) and take it out a little before being ready to pitch. There is discussion on the Northern Brewer forum as to the benefits of this if you are interested. But many other times I have just left my yeast starter at room temperature for 2 days and then pitched it straight into my cooled and aerated wort.

General Tips

1. It’s true: sanitizing is of

the utmost importance, especially before and during fermentation. Once your

beer has fermented it is not QUITE as critical, but still important. Just ask

yourself this question: has everything that is going to come into contact with

my beer been sanitized? When grabbing a spoon to stick into the beer think, has

this been sanitized? On brewing day things can go into the pot that have not

been sanitized because the wort will be boiled and that will kill any nasties.

2. Watch the temperature of

fermenting beer, especially in summer. Too cool is better than too hot. Try to

keep it in the 65-75 range, but I’d say 68-70 is optimal for ales. If you have

a fermometer this is very easy to tell. Otherwise get some cheap $2

thermometers from Target and set them by the carboy/fermenter. The actual

temperature of fermenting beer can be 5-8 degrees warmer than the surrounding

air temperature.

3. Even with screwing up a

number of things now and then, all of my batches have turned out great (except

for the one when the temps got up to 80 and were just too high for my fragile

Bitter to handle). So really it is not terribly hard to make good beer. The

above tips are in attempt to make even better beer. With each batch, a

homebrewer tries to improve little by little.

4. After you drink a homebrew,

rinse the bottle out well. I rinse it twice and then set it upside down to

dry. Since I’ve followed this practice, I have never washed my bottles again.

I do sanitize them of course, but I’ve never had to wash them. I suppose it

wouldn’t be a bad idea…

5. A final word about sanitizer. I used One Step for a couple years but have now switched to Star San. One Step is not technically a sanitizer by name, but it does the job. Star San IS technically a sanitizer and I feel does a more thorough job. Also, Star San can be saved in a clean container and used a number of times as long as its pH level still shows that it is acidic enough. You can buy some pH paper strips to test the pH level, and I have used Star San maybe 4-5 times over a period of many weeks with it still be acidic enough to do the job.

Relax, Don’t Worry, Have a Homebrew

popice@juno.com